The Hot Melt Adhesive & Films industry has witnessed significant advancements in recent years, driven by the demand for efficient, versatile, and durable bonding solutions. Modern manufacturing processes increasingly rely on adhesives and films not only to join materials but also to enhance product performance and longevity. One material that has gained prominence in this sector is TPU nonwoven fabric, which offers unique properties that improve comfort, flexibility, and protection across various applications. Understanding how TPU nonwoven fabric integrates with adhesives and films can provide valuable insights for manufacturers seeking innovative solutions in industries ranging from healthcare to textiles and packaging.

Understanding TPU Nonwoven Fabric

TPU nonwoven fabric, or thermoplastic polyurethane nonwoven fabric, is a material characterized by its lightweight, flexible, and breathable structure. Unlike traditional woven textiles, nonwoven fabrics are manufactured by bonding fibers together through mechanical, thermal, or chemical methods rather than weaving. This results in a fabric that is uniform, strong, and adaptable to various uses.

The addition of TPU, a type of thermoplastic elastomer, enhances the properties of nonwoven fabric by making it waterproof, elastic, and resistant to abrasion. This combination allows the fabric to maintain flexibility while providing protective barriers, making it ideal for applications where both durability and comfort are required.

Applications Across Industries

Healthcare and Medical Products

In the healthcare sector, TPU nonwoven fabric is widely used in surgical gowns, drapes, masks, and protective covers. Its waterproof nature prevents fluid penetration, while its flexibility ensures comfort for long hours of wear.

When used with hot melt adhesives and films, TPU nonwoven fabric can be laminated to other layers or coated to enhance barrier properties. This combination improves the overall performance of medical textiles, ensuring safety without compromising breathability.

Textile and Apparel Industry

TPU nonwoven fabric is increasingly used in the production of functional garments, including rainwear, sports apparel, and protective clothing. Its elasticity allows for comfortable movement, while its lightweight structure ensures minimal bulk.

Adhesives play a key role in bonding TPU nonwoven fabric to other materials or incorporating films for waterproofing, reflective surfaces, or decorative features. Hot melt adhesives, in particular, provide strong, flexible bonds that maintain the fabric’s natural stretch and flexibility.

Footwear and Accessories

In footwear, TPU nonwoven fabric is often used in insoles, linings, and moisture-proof layers. The material’s combination of elasticity and waterproofing ensures that shoes remain comfortable and durable under repeated stress.

By integrating TPU nonwoven fabric with adhesive films, manufacturers can create multi-layered assemblies that are lightweight yet strong, improving both performance and longevity. These methods are particularly effective in producing waterproof footwear, athletic shoes, and outdoor gear.

Packaging and Industrial Applications

Beyond textiles and healthcare, TPU nonwoven fabric finds applications in packaging and industrial settings. Its waterproof and elastic properties make it suitable for protective covers, bags, and industrial membranes. Laminating TPU nonwoven fabric with films using hot melt adhesives enhances its structural integrity while maintaining flexibility.

In industrial filtration, TPU nonwoven fabrics combined with adhesive films can create breathable yet durable barriers, ensuring efficiency and long-term performance in challenging environments.

Advantages of TPU Nonwoven Fabric

Lightweight and Flexible

One of the most notable benefits of TPU nonwoven fabric is its lightweight and flexible nature. It can be incorporated into products without adding significant weight or bulk, making it ideal for wearable items and portable applications.

Waterproof and Breathable

TPU nonwoven fabric is inherently waterproof while maintaining breathability. This dual property makes it suitable for protective clothing, medical textiles, and outdoor gear, where comfort and protection are equally important.

Durable and Elastic

The combination of TPU and nonwoven fibers provides excellent elasticity and resistance to wear and tear. This ensures that products made with TPU nonwoven fabric maintain their shape, durability, and performance even under repeated use.

Compatibility with Adhesives and Films

TPU nonwoven fabric bonds well with various adhesives and films, particularly hot melt adhesives. This compatibility allows manufacturers to create layered assemblies with enhanced barrier properties, water resistance, and mechanical strength without compromising flexibility.

See also: Best Recruitment Agencies in Tanzania for Hiring and Career Growth

Best Practices for Working with TPU Nonwoven Fabric

Surface Preparation

For optimal adhesion, TPU nonwoven fabric should be clean and free from contaminants such as dust, oils, or residual processing chemicals. Proper surface preparation ensures that adhesives and films bond effectively, resulting in durable and reliable assemblies.

Temperature and Pressure Control

When using hot melt adhesives with TPU nonwoven fabric, controlling temperature and application pressure is critical. Overheating can damage the material, while insufficient heat may result in weak bonds. Following manufacturer guidelines ensures consistent results across production runs.

Layering and Lamination

TPU nonwoven fabric can be laminated with other films or fabrics to enhance performance. Proper alignment, tension, and even adhesive distribution are key factors to maintaining uniformity, flexibility, and durability in laminated products.

Sustainability Considerations

TPU nonwoven fabric, when combined with solvent-free adhesives, supports environmentally friendly manufacturing practices. Precise adhesive application reduces waste, and the lightweight nature of the fabric contributes to lower energy consumption during production and transportation.

Innovations and Industry Trends

The integration of TPU nonwoven fabric with hot melt adhesives and films has spurred numerous innovations in the Hot Melt Adhesive & Films industry. New adhesive formulations improve bonding strength and elasticity, allowing for more complex and high-performance assemblies.

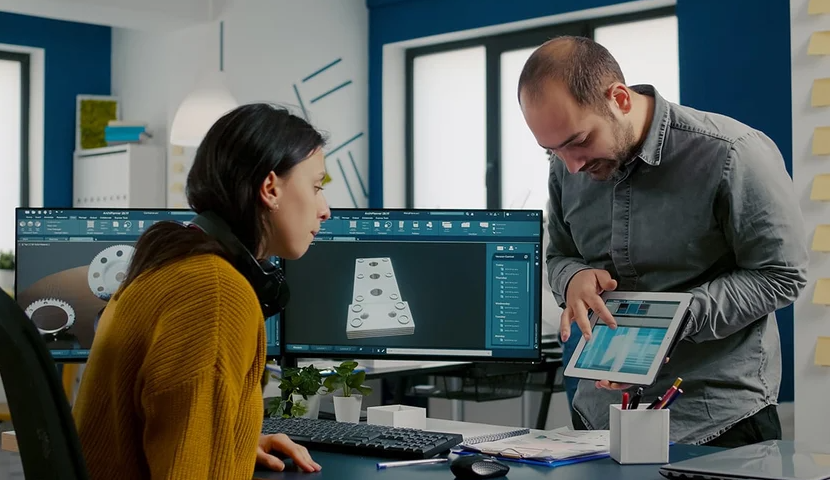

Automation and precision application equipment have enabled manufacturers to process TPU nonwoven fabric at higher speeds while maintaining consistent quality. Additionally, research into recyclable and bio-based TPU materials is paving the way for more sustainable production practices, making this technology both efficient and eco-conscious.

Conclusion

TPU nonwoven fabric has become a transformative material in the Hot Melt Adhesive & Films industry, offering flexibility, durability, and waterproof performance across a wide range of applications. From healthcare and textiles to footwear and industrial membranes, TPU nonwoven fabric combined with adhesives and films allows manufacturers to create innovative, high-performance products.

By understanding best practices, including surface preparation, temperature control, and lamination techniques, manufacturers can maximize the benefits of TPU nonwoven fabric while maintaining production efficiency and sustainability. As the industry continues to innovate, TPU nonwoven fabric is poised to play an increasingly important role in driving product performance, versatility, and environmental responsibility.