The demand for high-quality, durable, and precise components is continuously rising across industries such as automotive, aerospace, electronics, and industrial machinery. In this landscape, CNC machining of steel parts has emerged as a critical process, enabling manufacturers to produce complex and reliable components efficiently. By leveraging modern CNC technology, manufacturers can ensure consistency, accuracy, and superior performance in every production run. Machined metal parts, particularly steel components, play a pivotal role in enhancing the functionality and longevity of industrial equipment, vehicles, and consumer products.

Understanding CNC Machining of Steel Parts

CNC (Computer Numerical Control) machining is a process where pre-programmed computer software controls the movement of machinery and tools to remove material from a workpiece. This allows the creation of complex geometries, precise tolerances, and intricate details that would be difficult or impossible to achieve manually.

Steel is a preferred material for many applications due to its strength, durability, and versatility. CNC machining steel parts combines the benefits of high-quality material with the precision and repeatability of computer-controlled processes, resulting in machined metal parts that meet strict dimensional and functional requirements.

Advantages of CNC Machining Steel Parts

High Precision and Accuracy

One of the most significant advantages of machined metal parts is the ability to produce components with extremely tight tolerances. This level of accuracy ensures that machined metal parts fit perfectly within assemblies and perform reliably under demanding conditions.

Versatility in Design

CNC machining allows manufacturers to produce a wide range of shapes and sizes, from simple cylindrical components to highly intricate parts with complex features. This flexibility supports innovative product designs and ensures that components meet specific functional requirements.

Durability and Strength

Steel is known for its high strength and resistance to wear, making it ideal for applications that involve heavy loads, high pressure, or extreme conditions. Machined metal parts made from steel maintain their structural integrity over long periods, reducing maintenance costs and extending equipment lifespan.

Consistency in Production

CNC machining offers repeatable results, ensuring that each batch of machined metal parts meets consistent quality standards. This reliability is essential for industries that require large-scale production without compromising precision.

Cost-Effectiveness

While CNC machining may involve upfront investment in equipment and programming, the process reduces waste, minimizes labor costs, and allows for faster production cycles. Over time, this results in cost savings, especially for high-volume manufacturing.

Applications of Machined Steel Parts

Machined metal parts are utilized in a wide range of industries due to their strength, precision, and adaptability.

Automotive Industry

In automotive manufacturing, CNC-machined steel parts are used for engine components, transmission systems, suspension elements, and structural supports. The combination of precision and durability ensures that vehicles operate efficiently while meeting safety and regulatory standards.

Aerospace

The aerospace sector relies on high-strength, lightweight, and precise components for aircraft engines, landing gear, structural frames, and control systems. CNC machining steel parts provides the necessary precision and reliability for critical applications where performance and safety are paramount.

Industrial Equipment

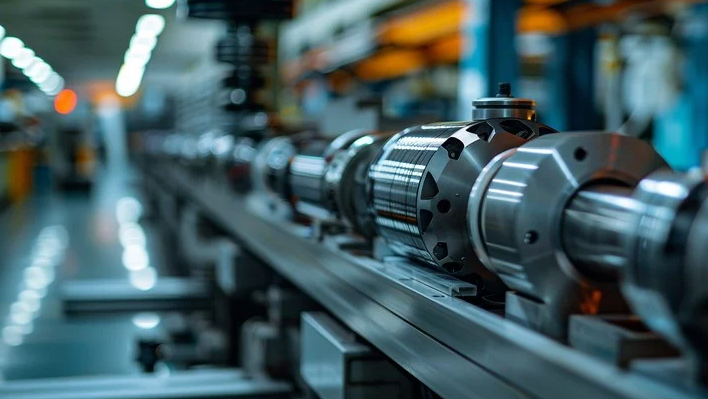

Industrial machinery demands components that can withstand high stress, friction, and repetitive use. Machined metal parts such as gears, shafts, and brackets maintain dimensional accuracy and operational efficiency even under extreme conditions.

See also: Top 10 Emerging Tech Trends That Will Shape 2025

Electronics and Electrical Equipment

In electronics, CNC-machined steel components are often used for protective housings, structural supports, and heat-dissipating parts. Steel’s thermal and mechanical properties enhance the durability and functionality of electronic devices.

Consumer Products

Machined steel components are also found in everyday products, including home appliances, tools, and recreational equipment. The precision and strength of these parts contribute to product reliability and user satisfaction.

The CNC Machining Process for Steel

The production of machined metal parts involves several stages to ensure quality and precision:

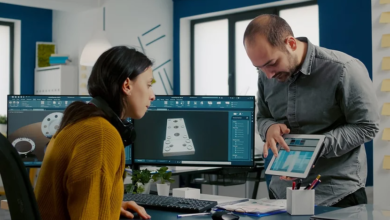

- Design and Programming: Engineers create CAD (Computer-Aided Design) models of the component and translate them into CNC programs using CAM (Computer-Aided Manufacturing) software.

- Material Selection: High-quality steel is chosen based on the required mechanical properties, corrosion resistance, and application needs.

- Machining Operations: CNC machines perform cutting, drilling, milling, turning, and grinding to remove material and achieve the desired shape.

- Finishing Processes: Additional processes such as deburring, polishing, or coating may be applied to improve surface finish, durability, and aesthetics.

- Quality Inspection: Rigorous quality checks, including dimensional measurements, hardness testing, and visual inspection, ensure that machined metal parts meet specifications.

Quality Control and Standards

A reliable CNC machining service ensures that all machined metal parts adhere to strict quality standards. Techniques such as coordinate measuring machines (CMM), optical inspections, and metallurgical testing help detect defects early and maintain consistent performance. High-quality control reduces the risk of part failure, enhances product reliability, and strengthens customer confidence.

Innovations in CNC Machining Steel Parts

Modern CNC machining has evolved significantly with technological advancements:

- Multi-axis CNC machines: Enable complex geometries and simultaneous operations, reducing production time.

- Advanced steel alloys: High-performance steels provide enhanced strength, corrosion resistance, and wear resistance.

- Automation and robotics: Improve efficiency, consistency, and safety by reducing human intervention.

- Simulation software: Optimizes tool paths and machining parameters to minimize errors and maximize productivity.

Sustainability and Efficiency

Sustainability has become an essential aspect of modern manufacturing. CNC machining steel parts minimizes material waste through precise cutting and optimized machining strategies. Additionally, modern machines are more energy-efficient, and scrap steel can be recycled, reducing environmental impact while maintaining high production standards.

Future Prospects

The demand for CNC-machined steel parts is expected to grow across industries, driven by the need for high-performance, durable, and precise components. As CNC technology continues to evolve, manufacturers will benefit from faster production, greater flexibility in design, and improved quality control. Machined metal parts will remain a cornerstone of industrial and commercial manufacturing, supporting innovation and enabling the creation of products that meet the demands of a competitive market.

Conclusion

CNC machining steel parts has transformed the manufacturing industry by combining precision, efficiency, and durability. Machined metal parts serve a wide range of industries, from automotive and aerospace to industrial machinery and consumer products, delivering components that are strong, reliable, and accurately produced.

By leveraging advanced CNC technology, high-quality steel, and rigorous quality control, manufacturers can meet the growing demand for durable and precise components. The continued evolution of CNC machining processes promises enhanced capabilities, increased efficiency, and sustainable production practices, solidifying the role of machined metal parts as essential elements in modern manufacturing.