Introduction

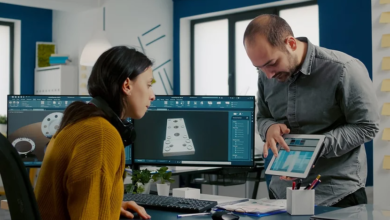

The metal fabrication industry has seen significant transformation over the past few decades, thanks to the integration of advanced machinery and automation. One of the most important innovations is the development of industrial press brakes, which provide manufacturers with the ability to bend, shape, and form sheet metal with precision and efficiency. Among these machines, the industrial series nc press brakes have become a popular choice due to their versatility, reliability, and ability to streamline production. These machines cater to industries such as automotive, aerospace, construction, and heavy machinery, where precision and repeatability are critical. Understanding the features and advantages of industrial press brakes is essential for businesses aiming to optimize production, reduce errors, and maintain high-quality standards.

Understanding Industrial Press Brakes

What Makes Them Unique

Industrial press brakes are designed to handle heavy-duty metal forming tasks with accuracy. Unlike standard or manually operated machines, these press brakes are equipped with numerical control (NC) systems that allow operators to program bend sequences, angles, and dimensions. This eliminates the need for repetitive manual adjustments and ensures consistent results across multiple workpieces.

The industrial series nc press brakes take this a step further by offering a combination of automated functions and robust construction, which allows for the bending of thicker and more complex materials without compromising precision. These machines are particularly useful for manufacturers who need to produce large quantities of parts while maintaining tight tolerances.

Key Components

Familiarity with the main components of industrial press brakes is crucial for safe and efficient operation:

- Ram or Punch: The moving component that applies force to the metal, creating a bend.

- Die: The stationary tool that shapes the sheet metal during the bending process.

- Back Gauge: Ensures precise positioning of the workpiece along various axes.

- Control Panel: Allows operators to program sequences, adjust angles, and control the machine’s automated functions.

- Safety Systems: Includes light curtains, guards, and emergency stops to protect operators during operation.

By understanding these components, operators can make full use of the industrial series nc press brakes while minimizing errors and ensuring workplace safety.

Advantages of Industrial Press Brakes

High Precision

Industrial press brakes provide a level of precision that is difficult to achieve with manual machines. The NC control system allows operators to set exact bend angles and dimensions, ensuring that each workpiece meets specifications. This precision is particularly important in industries such as aerospace and automotive manufacturing, where even small deviations can affect performance and safety.

Increased Productivity

Automation and programming capabilities industrial series nc press brakes allow industrial press brakes to perform complex bends in a single setup. This reduces the need for multiple setups or manual adjustments, saving time and increasing throughput. Operators can store programs for repeat production runs, ensuring consistent results without additional effort.

Versatility

The industrial series nc press brakes are capable of handling a wide variety of materials, thicknesses, and bending operations. From thin sheets to heavy-gauge metals, these machines provide the flexibility to produce diverse components without frequent tooling changes. This versatility makes them suitable for a broad range of manufacturing applications.

Reduced Material Waste

Accurate bending and repeatable operations reduce material waste. By minimizing errors and ensuring that components meet specifications on the first attempt, industrial press brakes contribute to cost savings and support sustainable manufacturing practices.

See also: Top 10 Emerging Tech Trends That Will Shape 2025

Operating Industrial Press Brakes

Safety Considerations

Safety is critical when operating any press brake:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and steel-toed shoes.

- Ensure that guards, light curtains, and emergency stops are functioning properly.

- Follow all manufacturer and workplace safety protocols.

By adhering to safety standards, operators can prevent accidents and maintain productivity.

Setup and Preparation

Proper setup is essential for achieving quality results:

- Select punches and dies suitable for the material type and thickness.

- Position and secure the sheet metal to prevent movement during bending.

- Verify that the NC system is programmed with the correct angles, dimensions, and sequences.

A precise setup ensures accurate bends and reduces the risk of errors or material damage.

Programming and Operation

The industrial series nc press brakes rely heavily on programming for efficient operation:

- Enter material type, thickness, and workpiece dimensions into the control panel.

- Program the desired bend angles, radii, and sequence steps.

- Save programs for repeated use to minimize setup time for future production runs.

Accurate programming ensures consistency, reduces human error, and allows operators to focus on monitoring the process rather than performing manual adjustments.

Inspection and Adjustment

After bending, it is important to inspect the workpieces:

- Verify that angles and dimensions meet specifications.

- Check for defects such as overbends, underbends, or material deformation.

- Make necessary adjustments to the program or machine settings before proceeding with additional pieces.

Regular inspection helps maintain quality standards and prevents issues from affecting large production batches.

Maintenance and Troubleshooting

Routine Maintenance

Regular maintenance ensures the longevity and optimal performance of industrial press brakes:

- Lubricate moving components to prevent wear.

- Inspect punches, dies, and hydraulic systems for damage or wear.

- Test safety devices to confirm proper functionality.

- Check the NC control system and calibrate axes as needed.

Routine maintenance minimizes downtime, improves efficiency, and prolongs the life of the machine.

Troubleshooting Common Issues

Operators may encounter issues such as:

- Misaligned bends: Adjust the back gauge or reposition the workpiece.

- Inconsistent angles: Inspect tooling, verify programming, and recalibrate the machine.

- Machine malfunctions: Check hydraulic and electrical systems and consult troubleshooting guides provided by the manufacturer.

Quickly addressing these issues ensures smooth production and prevents costly mistakes.

Training and Best Practices

Operator Training

Comprehensive training is essential for maximizing the efficiency and safety of industrial press brakes:

- Understand all machine components and their functions.

- Learn proper programming techniques and NC system usage.

- Practice safe operation and emergency procedures.

Well-trained operators contribute to consistent production quality and a safer work environment.

Promoting a Safety Culture

A strong safety culture is critical in manufacturing:

- Encourage reporting of hazards and unsafe practices.

- Enforce adherence to standard operating procedures.

- Conduct regular safety meetings and refresher training sessions.

A safety-focused culture reduces accidents and maintains operational efficiency.

Conclusion

Industrial press brakes, particularly the industrial series nc press brakes, have transformed the metal fabrication industry by combining precision, automation, and versatility. These machines enable manufacturers to produce complex bends accurately, efficiently, and consistently, meeting the high standards required in industries such as aerospace, automotive, and construction. Proper setup, accurate programming, adherence to safety protocols, and routine maintenance are essential for maximizing the benefits of industrial press brakes. By leveraging these advanced machines, manufacturers can reduce errors, minimize material waste, and enhance overall productivity, securing a competitive advantage in modern manufacturing.